MUSCAT: Leading greentech company, Envorem, has successfully piloted in Oman a new technology to treat sludge and oil-contaminated soil. UK-based Envorem processed sludge extracted from a pit and directly from tankers of majority state-owned Petroleum Development Oman (PDO), the country’s largest oil and gas producer. The technology, developed together with the University of Brighton, uses a little-known property of water to inexpensively process oil production sludge.

Everyday, the oil and maritime industries discard the equivalent of more than one million barrels of crude as hazardous waste creating huge environmental and financial problems. Crude and fuel oils contain contaminants comprising sediments and water that create an oily sludge.

The usual disposal routes for these wastes is incineration or dumping into open, polluting pits. However, the sludge remain and will eventually have to be incinerated generating around 1.5 tonnes of carbon dioxide per tonne incinerated sludge.

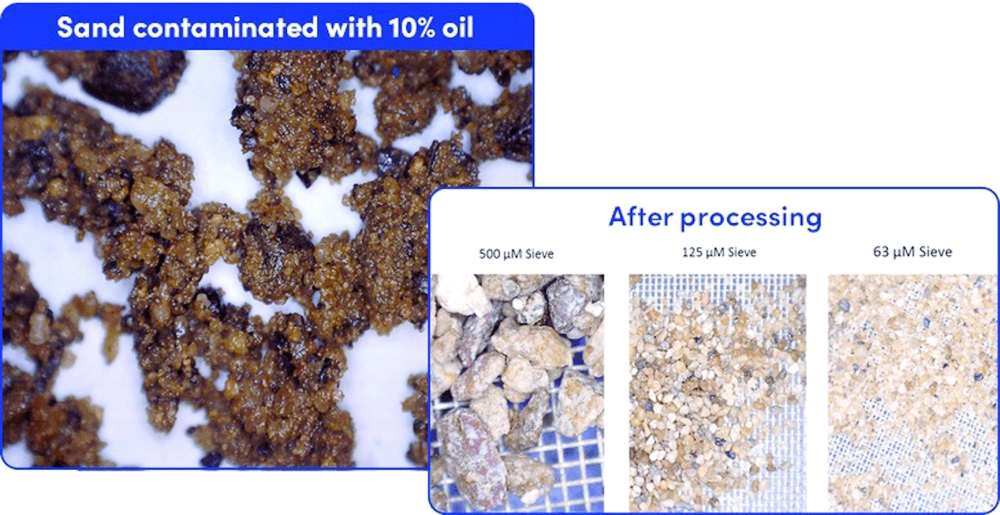

Envorem’s technology uses very little energy to disassemble sludge, clean the solids and recover the entrained oil for recycling — all without using chemicals or generating emissions.

The pilot in PDO resulted in the system being operated at a steady state of 2 tonnes sludge or soil per hour and more than 99 per cent of the hydrocarbons were recovered. The system is designed to be highly efficient, cost-effective, and environmentally friendly, with minimal waste and emissions.

Mark Batt-Rawden, CEO of Envorem, said, “The issue until recently has not attracted the public’s attention but that is changing as the environmental impact of ongoing oil production and legacy pollution is increasingly appreciated.”

The pilot proved the technology generates a fraction of the emissions of thermal treatment and is both cheaper and faster.

According to Envorem, 99 per cent of the oil was removed from sludge as crude of usable quality — a double benefit; reducing the need for extraction and its associated carbon footprint, plus saving emissions from disposal by incineration.

“The oil industry has been seeking a solution for decades but nothing has ever proved effective and viable. It has taken us over 10 years to get this technology right and the solution we have developed pushes the boundaries of technology in a number of areas,” Mark Batt-Rawden said.

Envorem’s core technology combines established techniques with hydraulic shock and cavitation, where bubbles are created by the vaporisation of water, a phenomenon copied from the natural world. Cavitation can be generated ultrasonically, electrically, or physically and is widely known as a parasitic effect that destroys propellers on ships and the impellers of pumps.

“As the world transitions towards a low-carbon future it is crucial that we continue to mitigate against the environmental impact of ongoing oil production and ensure the legacy pollution is addressed. Now we can remove the barriers to act differently by providing a way to spend less and simultaneously reduce pollution,” the CEO added.

Oman Observer is now on the WhatsApp channel. Click here